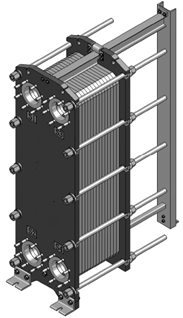

Brief Introduction of Plate Heat Exchanger

Plate Heat Exchanger comprise of a series of corrugated plate which was installed together. There are two channels among the plates which are loaded with cold and hot medium separately. Cold and hot medium are counter flowing separately on the two sides of plates. The product is characterized by compact design and high heat transfer efficiency.

Material of Plate

Materials of Common-used plates are as follows: Stainless steel AISI304, 316,316L, Titanium

Sealing Material

Sealing material which are frequently used and its scope of application are as follows.

Material |

Temperature Range ℃ |

Medium |

|

NBR |

<135 |

Water, food industry, hydrocarbon, mineral oil, fatty oil |

|

EPDM |

<165 |

Hot water,vapor,weak acid, weak base |

|

FPM |

<180 |

High concentration inorganic acid, high temperature mineral oil |

|

NEOPRENE |

<100 |

Ammonia, Containing fluorine refrigerants |

Usage of PHE

QingPu’s equipment with heat energy and heat exchange function are widely used for industries of supply heating, air conditioning, machinery, metallurgy, food, chemical, medicine, marine, etc. This equipment can be applied to all process occasions like heat exchanging between liquid and liquid, heat exchanging between condensing-gas and liquid.

HVAC

Region supplying heating, central air-conditioning, water (ground) source heat pump, ice-making cool storage system, and pressure cut-off in the high-rises buildings, waste heat recovery, life hot water, and swimming pool heat up.

Electric Power

Circulating water cooling, wash coolant cooling, transmission oil cooling, water cooling for generator armature and stator, transformation oil cooling, cable oil cooling, cogeneration.

Iron and steel industry

Mould cooling, continuous casting machine cooling, hydraulic oil cooling, stove water cooling, coking water cooling, emulsion cooling, ammonia liquid cooling, machine coolant cooling, compressor coolant cooling, feed water cooling.

Automobile industry

Quenching oil cooling, paint cooling, phosphate treatment fluid cooling.

Marine and Generator

Central cooling, lubrication oil cooling, piston coolant cooling, transmission oil cooling, heavy fuel oil cooling, diesel preheating, sea water heat up.

Mechanical Industry

Machine cooling, emulsion cooling, hydraulic oil cooling, grinding oil cooling, furnace water cooling, transmission oil cooling, generator coolant cooling, heat recovery, autoclave water cooling.

Petrochemical Industry

Alkali liquor cooling, acid liquor cooling, chlorine liquor cooling, saline water preheating, potassium carbonate liquor cooling, paraffins cooling, soap liquor cooling, mineral oil cooling, inner fat solution cooling, paste shampoo cooling, paint craftwork cooling.

Food Beverage Industry

Primary fruit juice heat up, confiture heat up, milk pasteurization and cooling, carbon acid gas fruit juice heat up, syrup heat up, fruit juice heat up, heating and cooling of papaya alcohol, heating and cooling of all kind of liquor, heating and cooling of edible oil, fatty acid cooling.

Paper Industry

Waste water cooling, wash water cooling, recovery of waste hot water, condensing of wood pulp.

Plate and Gasket

Product Characteristic

1.Uniform distribution flow rate is achieved in “Chocolate” bypass flow area, remove the flow rate dead area and then avoid no uniform flow rate distribution and decreasing heat exchange efficiency that produce by flow dead angle, pitting, scaling.

2,Pumpheat sealing gasket (exempt bonded-seal) technology makes the installation of sealing gasket easier, furthermore, the embossment which locates at the outside of sealing gasket perfectly fit the groove on the back side of another plate to lock the plates when clamping, avoiding misplace. |