Brief Introduction of Heat Exchanger Unit

It is a combination which comprises pump, heat exchanger, valve, sensor, control module, and meets the requirement of temperature and pressure. It is a system that design by customer and us together.

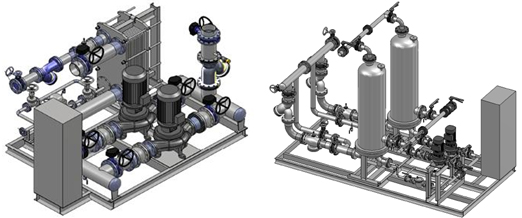

Figuration of Heat Exchange Unit

PHE unit are frequently applied to heat exchange processes like concentrated heating (H), refrigeration (A), heating in swimming pool (B) and process (P).

Tube and Shell heat exchange unit are commonly used for life hot water (B) supply system.

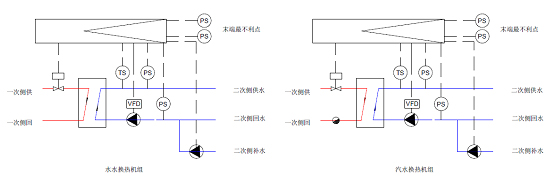

Working Principle of PHE Unit

Source of heat which come from factory of source of cold go through filter; electric control valve controls flow rate; reach the heat exchanger and exchange the heat with secondary side net medium, then come back factory of source of heat. Secondary side medium pass through heat exchanger and exchange heat that is drive by circulating pump, supply to the user; It will come back to heat exchange unit from user.

Unit Control Method

Temperature Control (T)

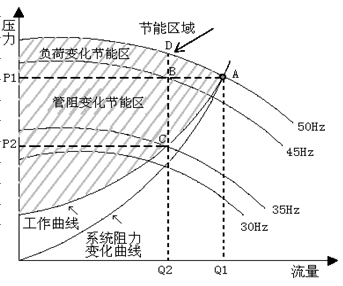

●Adjust primary side flow rate and ensure secondary side water temperature constant. Generally, 30% heat source could be saved.

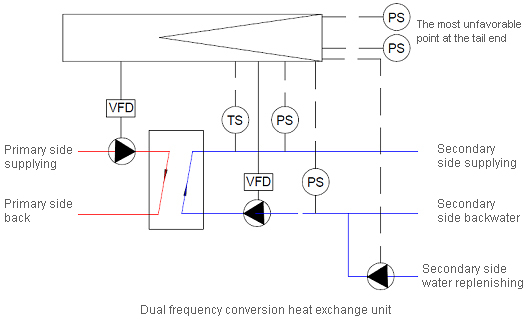

● Pumpheat particular has dual converter technique. Converting frequency by primary pump could save 50% electric power of primary pump.

● Outdoor temperature compensation: when outdoor temperature is higher than setting centigrade, secondary side water temperature could be revised according to the customers requirement. (For heating usage)

Variable Pressure Difference Control(P)

● Pumpheat twice converter technique and circulating pump variable pressure difference control are applied, variable pressure difference sensor is fixed at the most unfavorable point at the tail end, then using working condition frequency conversion control circulating pump to meet requirement of system variable pressure difference, to save pump energy 50%.

Voltage stabilization control(J)

● stops working automatically and close the electric control valve, then automatic water replenishing pump starts working.

Other Function of Unit

Full-automatic Operation

Qingpu heat energy and heat exchange unit adopts “one key”auto-run project to avoid high limit the loss which mal-operation brings. After power is on, controller is working, unit is sequence starting after self –checking.

Remote Control

Qingpu heat energy and heat exchange unit controller reserve passive stem node communication interface. We can collect and observe unit water outlet temperature, pressure, electric control valve aperture, water pump operation status, frequency and failure alarm. RS485 connection could be provided to open communication protocol.

Protection Function

● When secondary side supplying water temperature exceeds setting temperature, electric control valve will close automatically to avoid out of control and execute over temperature protection.

● All setup parameters and running status parameters keep the data before setting after the power is off to execute power-ff protection.

● When secondary side backwater pressure exceed standard, safe valve automatically open and starts to decompression.

● Every time, start different pump to ensure the running time of each water pump is roughly identical to execute timing switchover function.

● Once unit was inspected that there was any malfunction, it would send out alarming signal automatically.

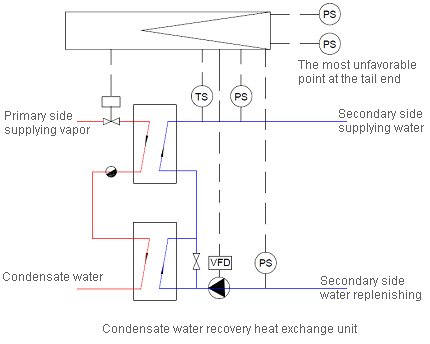

Condensate Water Recovery Function

Condensate water recovery technology which Pumpheat initiates can recover 20% of condensate water in vapor water heat exchange unit, it was wasted usually!

|